Laminated Glass

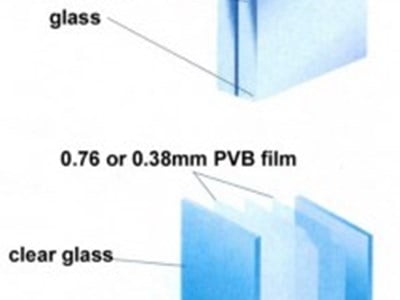

Laminated glass is a type of safety glass that holds together when shattered. In the event of breaking, it is held in place by an inter-layer, typically of polyvinyl butyral (PVB), between its two or more layers of glass.

The inter-layer keeps the layers of glass bonded even when broken, and its high strength prevents the glass from breaking up into large sharp pieces. This produces a characteristic “spider web” cracking pattern when the impact is not enough to completely pierce the glass.

The PVB inter-layer also gives the glass a much higher sound insulation rating, due to the damping effect, and also blocks 99% of incoming UV radiation.

What is it used for ?

Typically, Laminated glass is normally used when there is a possibility of human safety or security risk or where the glass could fall if shattered.

Laminated glass is often used in exterior shop fronts, curtain walls and windows. low level glazed areas and areas surrounding entrance ways and doors and additionally in overhead or roof glazing.

If there is a risk of breakage through accidental contact then laminated glass must be considered. Most safety glass consists of 2 leaves of the same thickness of float glass along with one interlayer of either 0.38 or 0.76 thickness.

Types of laminated glass:

Ordinary transparency and colour laminated, coated & laminated, tempered & laminated, Low-E laminated, arts laminated, heat bending laminated, as well as bullet-proof glass and laminated glass and aquarium glass.

Bulletproof glass

Also known as ballistic glass or bullet-resistant glass is a type of strong but optically transparent material that is particularly resistant to being penetrated when struck. Like any material, however, they are not completely impenetrable. It is usually made from a combination of two or more types of glass, one hard and one soft. The softer layer makes the glass more elastic, so it can flex instead of shatter.

Bulletproof glass varies in thickness from 3/4 in. to 3.5 in. (19mm to 76mm)